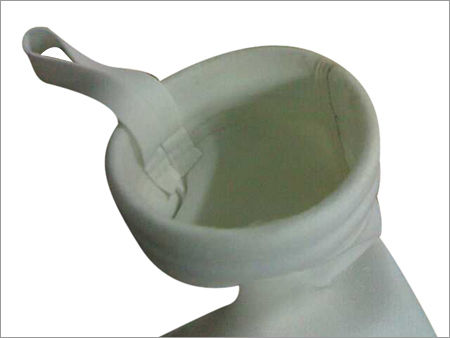

Snap Type Dust Collector Bags

Snap Type Dust Collector Bags Specification

- Resistance

- Low

- Diameter

- 130 mm

- Efficiency (%)

- 99%

- Thickness

- 1.7 mm

- Thermal Shrinkage

- 1% at 150C

- Working Temperature

- 70C to 150C

- Application

- Dust Collection in Industrial Applications

Snap Type Dust Collector Bags Trade Information

- Minimum Order Quantity

- 500 Packs

- Payment Terms

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque

- Delivery Time

- as per requirment Days

About Snap Type Dust Collector Bags

We are globally acknowledged manufacturer, exporter and supplier of a superior quality range of Snap Type Dust Collector Bags that are used for collecting dust in various industries. Our seasoned professionals utilize premium grade fabric with the help of latest techniques in the designing and manufacturing process of the offered bags. Provided Snap Type Dust Collector Bags are available in two types like Snap Type Poly-phenylene Sulphide Bag and Snap Type Homo Polymer Poly-acrylonitrile Bag in different sizes. Customers can easily avail these bags as per their needs at reasonable rates.

Features:

-

Optimum strength

-

Seamless stitching

-

Easy installation

-

Durability

High-Efficiency Filtration for Demanding Industries

The Snap Type Dust Collector Bags are meticulously constructed to deliver a dust collection efficiency of up to 99%, catering to environments such as cement factories, steel mills, power plants, and pharmaceutical production units. The superior moisture resistance, low-pressure drop, and double-stitched seams guarantee lasting performance even in conditions with high particulate loads and variable humidity.

Engineered for Robust Performance and Durability

These collector bags utilize high-quality fabric treated with singeing and calendering, enhancing particle release and minimising dust cake formation. The bags resistance to harsh temperatures (up to 150C) and minimal thermal shrinkage (1% at 150C) assure reliable filtration over extended periods. Their 1.7 mm thickness ensures both strength and flexibility, with a white finish that blends seamlessly in industrial setups.

FAQs of Snap Type Dust Collector Bags:

Q: How are Snap Type Dust Collector Bags installed in industrial systems?

A: These bags are designed with snap bands that allow for easy installation and secure fitting into most standard dust collector systems. Simply insert the bag into the cage, secure the snap band to the cell plate, and ensure the seal is even for optimal dust containment.Q: What industries are best suited for these dust collector bags?

A: The bags are ideal for a range of environments including cement plants, steel production facilities, power generation units, and pharmaceutical manufacturing. Their moisture resistance and high filtration efficiency make them suitable for diverse industrial dust collection applications.Q: When should the Snap Type Dust Collector Bags be replaced?

A: Replacement is recommended when there is a noticeable drop in filtration efficiency, visible bag damage, or increased pressure drop across the system. Depending on working conditions, inspections should be conducted periodically to maintain optimal performance.Q: Where can I use these bags within my facility?

A: The bags are engineered for use in dust collection units, particularly where high temperatures, dust loads, or moisture are present. They fit standard dust collectors used in processing, production, and utility areas within industrial facilities.Q: What process ensures the bags durability and dust release?

A: Each bag undergoes singeing and calendering surface treatments, which enhance dust cake release and reduce clogging. The double-stitched seams add strength, securing longevity even in demanding operational environments.Q: How do these dust collector bags benefit industrial operations?

A: By capturing up to 99% of airborne particles, these bags help facilities maintain regulatory compliance, protect equipment from dust build-up, ensure cleaner air quality, and support safer working conditions.

- Minimum Order Quantity

- 500 Packs

- Delivery Time

- as per requirment Days

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Filter Bags Category

Candle Filter Bag

Minimum Order Quantity : 1000 Pieces

Working Temperature : 135 Celsius (oC)

Type : NonWoven Filter

Application : FILTRATION

Efficiency (%) : 99

Thermal Shrinkage : 3%

Collar Type Dust Collector Bags

Minimum Order Quantity : 500 Packs

Working Temperature : Up to 150C

Type : Other, Collar Type Dust Collector Bag

Application : Dust collection in industrial and commercial ventilation systems

Efficiency (%) : 99% at 5 microns

Thermal Shrinkage : <1% at 150C

Cassette Type Filter Bag

Minimum Order Quantity : 100 Pieces

Working Temperature : Up to 80C

Type : Other, Cassette type filter bag

Application : HVAC, clean rooms, pharmaceutical, ventilation systems

Efficiency (%) : Up to 99.99%

Thermal Shrinkage : <1% at 120C

Industrial Filter Bags

Minimum Order Quantity : as per requirment Pack

Working Temperature : Up to 130C

Type : Other, Bag Filter

Application : Dust collection, air filtration, industrial processing

Efficiency (%) : 99%

Thermal Shrinkage : 1% at 130C